High throughput production of pure wax jewelry patterns for lost wax casting

The ProJet MJP 2500W Plus is a 100% wax jewelry patterns 3D printer that adjusts to your workflow, delivering from several short-run batches a day to the next day for larger builds at high productivity. Combine fast print speeds and large build volume capacity for high productivity of precision, fine jewelry casting patterns with an affordable 3D printer.

High Productivity

From fast short runs to high throughput, the ProJet MJP 2500W Plus enables pure wax casting patterns high-volume production or rapid single-lane printing at fast print speeds to improve the casting room efficiency. With a large build volume capacity and 24/7 operation, the high productivity of this affordable printer means fast amortization and a high return on investment.

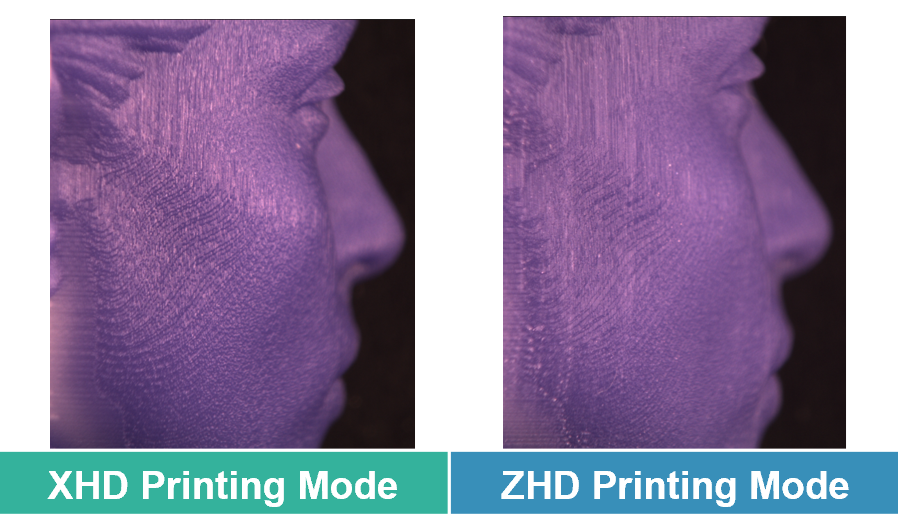

2 Printing Modes

- XHD: 1200 x 1200 x 1600 DPI – 16µm layers

- ZHD: 1200 x 1200 x 3200 DPI – 8µm layers

- Flexible, efficiency and high quality, printing freely based on different situations.

- Typical accuracy: ±0.0508 mm/25.4 mm (±0.002 in/in).

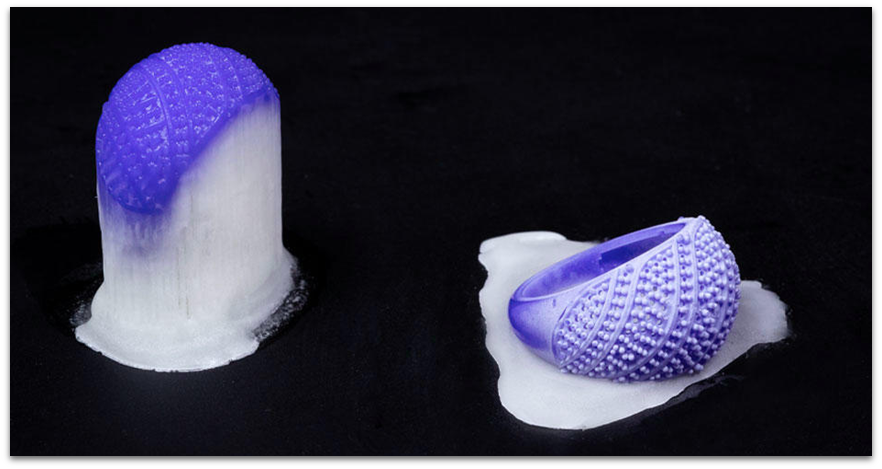

High Resolution Patterns

Consistently print true-to-CAD and fine feature definition jewelry patterns with exact, razor-sharp edges and extremely crisp details. Superior resolution and dissolvable and meltable supports result in excellent surface quality for reduced finishing labor and polishing of costly precious metals. These highly accurate, fine wax patterns are directly printed, without the time, costs and geometric limitations of tooling.

Casting Quality

The MJP 2500W Plus utilizes VisiJet® 100% wax materials to produce flexible and durable, high-quality jewelry patterns. These materials are designed to ensure reliable performance and consistent results when used with existing lost-wax casting processes and equipment.

VisiJet wax materials melt like standard casting waxes, resulting in defect-free castings with zero ash content. They are highly durable, making them ideal for handling and casting intricate features. Additionally, their high contrast colors enable easy visualization of fine details.

3D Sprint Software

Easy build preparation and file repair with

no additional software required

- Auto-Place parts

- Auto added support

- Support up to 16 types of 3d files

- Intuitive interface

- Eliminates the need for costly software seats by third party vendors

Ease-of-Use with Dissolvable Supports

- Batch processing efficiency

- Excellent surface quality

- Reduced finishing labor

- Reduced polishing of precious metals

- Supports for limitless geometries

MJP 2500W Plus Specifications

Printing Materials